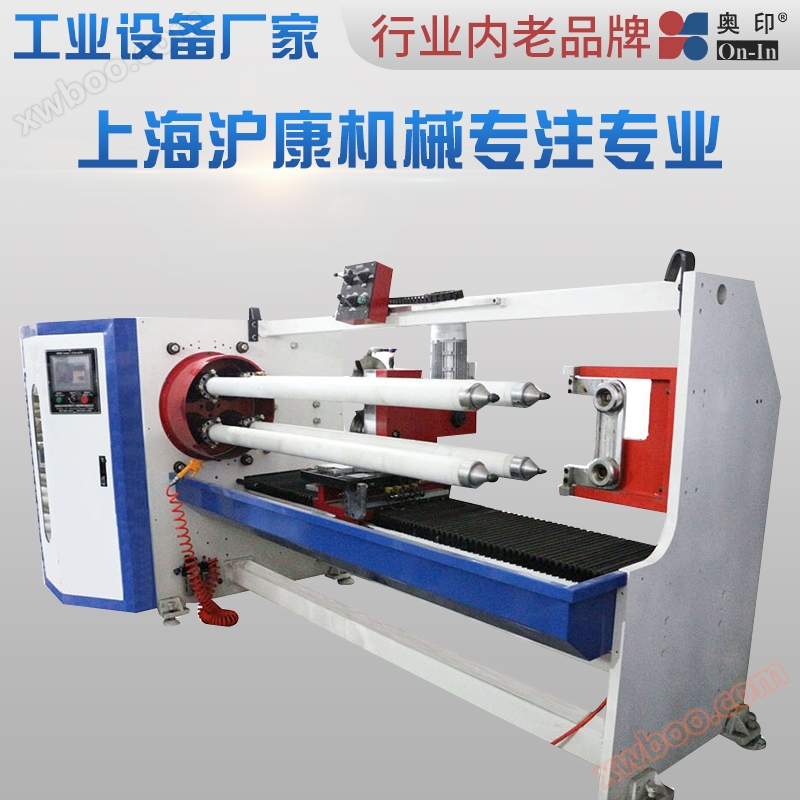

Flip the four axis cutting table

Suitable for slitting various adhesive tapes such as double-sided tape, masking tape, gold finger, waterproof tape, and non adhesive materials such as reflective film.

Features and Characteristics:

1Double blade dual axis cutting, alternating dual axis work between four axes.

2Imported ball screws and linear bearings are used.

3Automatically adjust the cutting angle.

4Round knife cutting,Automatic cooling and lubrication.

5Servo feed, servo motor controls cutting width.

6. Optional follow-up knife device for easy protection of the shaft when cutting small shafts

7The spacing between the two axes can be customized according to customers, such as:250mmThe distance between the axes

8Adopting a timed, quantitative, and automatic lubrication method to improve the service life of the screw and slide rail

Main technical parameters

|

Machine Specifications |

1300mm 1600mm |

|

width |

130mm 160mm |

|

Cutting precision |

±0.05mm |

|

Cutting diameter |

140mm (using a 76.2mm shaft), if a machine with a shaft spacing of 250mm is used, 180mm can be cut |

|

Cut paper core inner diameter |

25.4mm-76.2mm |

|

Knife diameter |

450mm |

|

Equipment power |

8kw |

|

power supply voltage |

380V 50HZ 3Ф |

|

Working pressure |

0.4-0.6MPa |

|

Overall dimensions |

2900 * 1750 * 1400mm (1300 model, 1600 model plus 300mm length) |

Recommended reading: These maintenance measures for the slitting machine are worth paying attention to Explanation of the structural advantages of the slitting machine Process requirements for fixed length cutting of slitting machine Analysis of the reasons for abnormal operation of the rewinder Choosing a slitting machine to master these methods is more reliable Analysis of specific steps for installing a slitting machine A Brief Discussion on the Reasons for Cutting Machine Jumping Blade The methods for maintaining the slitting machine are very scientific Daily maintenance and upkeep measures for slitting machine Detailed steps for installation and adjustment of slitting machine